Productive Nanosystems as a Milestone Toward Geoethical Nanotechnology

James B. Lewis, Ph.D.

Page 2 of 7

The crucial need for an atomically precise nanofabricator

A single atomically precise mechanism capable of manufacturing atomically precise mechanisms would quickly lead to factories capable of manufacturing macroscopic quantities of atomically precise products. A 2003 proposal by Chris Phoenix [8] for a primitive nanofactory considers how to go from a single nanoscale fabricator capable of using programmed mechanical motion for atomically precise manufacturing to a tabletop nanofactory composed of many small fabricators and capable of building complex human-scale products. Phoenix’s proposal avoids the issue of how to construct the first fabricator, but establishes that once such a fabricator is available, it might not take much longer to produce a practical nanofactory capable of manufacturing human-scale amounts of a wide variety of atomically precise products—including more nanofactories—because the design of such a nanofactory is within the reach of current engineering practice.

The nanofactory proposal assumes the existence of a small fabricator similar to earlier proposals by Ralph C. Merkle, for a double tripod mechanism capable of using mechanochemistry—forming and breaking covalent bonds by controlled mechanical motions—to build diamond-like products from carbon and hydrogen. It further assumes the nanofabricator is capable of performing within a nanoscale volume all of the mechanical motions necessary to fabricate parts from feedstock and assemble them into small devices comparable in complexity to the fabricator itself. Phoenix does not consider mechanical features smaller than 1 nm so that parts design generally simplifies to filling a given volume with bulk diamond lattice. Thus only a few reactions would be needed to produce a wide variety of molecular part shapes. The product of a single 200-nm nanofabricator would be a 200-nm nanoblock with a complex internal structure—typically a nanoblock might be comprised of 8000 10-nm parts, each comprising about 176,000 diamond-lattice atoms.

The next step up in the hierarchy of the nanofactory is a production module a few micrometers on a side, which consists of one nanocomputer and a few thousand nanofabricators, and which produces a few blocks, a few microns in size, by combining a few thousand nanoblocks. The modules would be hierarchically assembled by larger scale manipulator systems to form macroscale products by a process of convergent assembly, in which blocks are assembled to form larger parts, which are themselves assembled to form still larger parts, and so forth through more than a dozen stages.

In a 2005 paper [9] Phoenix proposes two different architectures for primitive molecular manufacturing systems that could be developed with today’s technology, yet suffice to begin the process of using simple systems to manufacture improved systems, thus initiating a cycle of rapid improvement. Unlike his 2003 proposal, which presumed the prior development of a nanofabricator capable of diamond mechanosynthesis, these architectures assume the availability of suitable molecular building blocks (MBBs) prepared by current chemical or biotechnical methods from DNA, proteins, related polymers, or other atomically precise nanostructures. Both architectures use simple systems to mechanically position various types of MBBs from solution to assemble larger products. Suitable MBBs could approximate 5-nm cubes containing thousands of atoms—large enough to include molecular actuators or molecular electronics components.

In these systems the convergent assembly design of the 2003 proposal is superseded by a planar assembly design, first put forward by John Burch and Eric Drexler, in which the fabricators are arranged as a thin plane with molecular feedstock supplied to one side of the plane to produce 100-nm to one-micrometer (1000 nm) scale building blocks within the plane, which are then assembled into product on the opposite side of the plane, one layer at a time. In this design, layer-by-layer construction eliminates the need to have multiple mechanisms for handling parts of multiple scales created at multiple stages of the convergent assembly process. This planar design is further elaborated in a more detailed paper co-written by Chris Phoenix and Tihamer Toth-Fejel for the NASA Institute for Advanced Concepts [10], which proposes a manufacturing system “simple enough to be assembled by a scanning probe microscope, but sufficiently functional to build parallel and improved versions.” Their analysis shows the planar assembly approach to have substantial advantages over other proposed architectures. The principal unsolved problem is how to fabricate atomically precise sub-micrometer functional block modules. To develop this fabrication capability, they propose a step-by-step process that starts with solution chemistry and self-assembly, proceeds by guided self-assembly and partial mechanosynthesis in solvent, introduces increasingly strong chemical bonds to fasten molecules together, and eventually arrives at machine-phase chemistry in a vacuum.

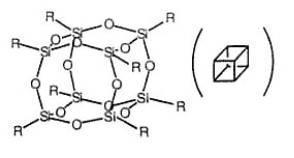

A silsesquioxane [RSiO1.5]8 molecule (as found at [and cited from]:

/www.chemistrymag.org/cji/2005/077048ne.htm

Jul. 2, 2005 Vol.7 No.7 P.48 Copyright CJI

Phoenix and Toth-Fejel consider possible molecular building blocks and conclude that the most promising option is the cubic silsesquioxane [RSiO1.5]8 molecule (sometimes known as POSS™), which is based on the core structure of silica. The rigid silica core of the molecule has eight vertices to which functional organic groups can be added to create organic molecules with diameters of one to two nanometers. Chemical methods are available to combine cubic silsesquioxanes to give rigid molecularly precise structures.

The net result from the above papers is that feasible ways forward can be outlined from two possible starting points: (1) a method of fabricating 200-nm-scale atomically precise building blocks by diamond mechanosynthesis, (2) methods to produce 5-nm-scale molecular building blocks of various compositions fabricated by self-assembly.

Productive nanosystems technology roadmap

Given plausible designs for primitive nanofactories, the question becomes how to fabricate the first nanofabricator and/or assemble the necessary set of molecular building blocks. The first systematic effort to address this challenge was made from 2005 through 2007 and led by Foresight Institute and Battelle [11]. The remainder of this article will review the principal conclusions of this first roadmap and summarize progress since 2007.

The Productive Nanosystems technology roadmap charts paths from current nanotechnology to atomically precise productive nanosystems (APPNs). APPNs are (1) nanoscale systems that are also (2) atomically precise manufacturing systems in which controlled sequences of operations build atomically precise structures, and (3) are themselves composed of atomically precise structures. Today, only biology provides examples of APPNs. Scanning probe microscopes provide limited ability to conduct atomically precise operations on surfaces. These are prototype atomically precise manufacturing systems, but they are neither nanoscale nor composed of atomically precise structures. Atomically precise products can be produced by self-assembly of either organic or inorganic molecules. The products produced may be useful for various applications, but so far not for building atomically precise manufacturing systems. The essential distinction between the goal of the Productive Nanosystems technology roadmap and many other fabrication processes widely used in current nanotechnology is control of product structure to atomic precision, as opposed to control of product structure to the scale of one to a hundred nanometers, which is precise enough to give rise to many very useful properties not seen with bulk materials, but is several-fold to several hundred-fold less precise than atomic precision.

The Productive Nanosystems technology roadmap charts paths from current nanotechnology to atomically precise productive nanosystems (APPNs). APPNs are (1) nanoscale systems that are also (2) atomically precise manufacturing systems in which controlled sequences of operations build atomically precise structures, and (3) are themselves composed of atomically precise structures. Today, only biology provides examples of APPNs. Scanning probe microscopes provide limited ability to conduct atomically precise operations on surfaces. These are prototype atomically precise manufacturing systems, but they are neither nanoscale nor composed of atomically precise structures. Atomically precise products can be produced by self-assembly of either organic or inorganic molecules. The products produced may be useful for various applications, but so far not for building atomically precise manufacturing systems. The essential distinction between the goal of the Productive Nanosystems technology roadmap and many other fabrication processes widely used in current nanotechnology is control of product structure to atomic precision, as opposed to control of product structure to the scale of one to a hundred nanometers, which is precise enough to give rise to many very useful properties not seen with bulk materials, but is several-fold to several hundred-fold less precise than atomic precision.

Two parallel pathways

The roadmap looks at how current methods of atomically precise manufacturing (APM) can be developed along two parallel pathways to reach the goal of APPNs. One path (tip-based) begins with scanning tunneling microscopes (STMs) or atomic force microscopes (AFMs) to pattern surfaces with atomic precision, and proceeds by using tip-array atomically precise manufacturing to produce layered crystalline structures of multiple materials. The other path is bio-based and begins with biopolymers produced by biological APPNs (ribosomes, DNA polymerases) or by solid phase organic synthesis. It involves the atomically precise self-assembly of modular molecular composite nanosystems (MMCNs) composed of building blocks of DNA, proteins, and other molecules and nanostructures to build three-dimensional frameworks of biopolymers to which various other components are attached.

Footnotes

[8] "Design of a Primitive Nanofactory” Chris Phoenix, Journal of Evolution and Technology 13 (October 2003) http://crnano.org/Nanofactory.pdf [accessed Feb. 16, 2009].

[9] "Molecular Manufacturing: What, Why and How" Chris Phoenix, published May 2005 http://www.crnano.org/...WhatWhyandHow.pdf [accessed Feb. 16, 2009].

[10] “Large-Product General-Purpose Design and Manufacturing Using Nanoscale Modules” Chris Phoenix and Tihamer Toth-Fejel, report to NASA's Institute for Advanced Concepts, presented May 2005 http://crnano.org/NIAC%20Paper.pdf [accessed Feb. 16, 2009].

[11] "The Technology Roadmap for Productive Nanosystems charts a path beginning with current nanotechnology capabilities to advanced systems. The Roadmap is a first attempt to lay out a step-by-step course of development that must take place to move from one stage to another, with milestones for achieving each step. With the support and collaboration of our partners, The Waitt Family Foundation and Battelle, we identify the gap between the basic nanostructured materials of today, and the potential of productive nanosystems."

—Foresight Nanotech Institute

http://www.foresight.org/roadmaps/index.html [accessed Feb. 7, 2009] The complete roadmap can be downloaded from this page as two PDF files:

Productive Nanosystems: A Technology Roadmap (198 pages, 2.1 MB PDF)

http://www.foresight.org/...

Working Group Proceedings (210 pages, 14.6 MB PDF)

http://www.foresight.org/...